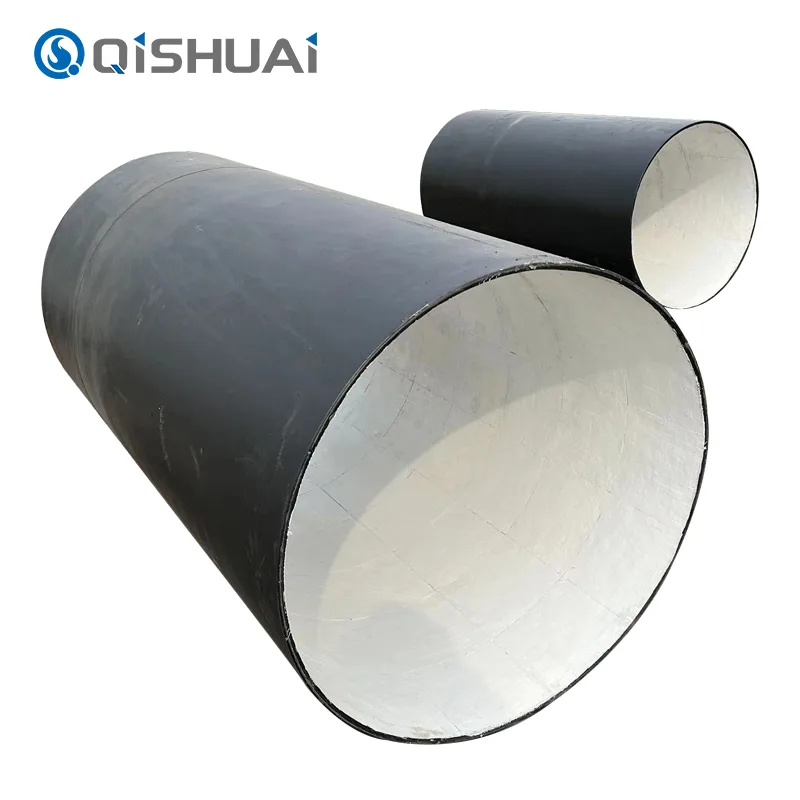

Shandong Qishuai Wear Resistant Equipment Co., Ltd. provides high-wear-resistance ceramic piping. We offer an extensive selection of alumina ceramic lined tubes, we can also provide customized and wholesale services, and quality assurance for worldwide delivery.

We offer overall technical solutions with highly wear resistant and low maintenance cost for mining, power, steel mill, sand pump conveyance and powder handling industries.

Our alumina ceramic lined pipe range encompasses five core products, all benefiting from factory-direct supply and one-stop procurement:

Isostatic Pressing Ceramic Wear Tube

Al₂O₃ Ceramic Wear Pipe

Shandong Qishuai Wear-Resistant Equipment Co., Ltd. possesses advanced production lines including isostatic pressing, cold isostatic pressing (CIP), dry pressing, wet grouting, and automated laser welding. This ensures each alumina ceramic liner pipe exhibits consistent density, wear resistance, and impact resistance. With over a decade's specialisation in export markets, our products serve over 80 countries worldwide, maintaining long-term supply partnerships with major mining and power generation enterprises across Europe, Australia, and Southeast Asia.

Additionally, we offer value-added services including custom sizing, sample installation trials, engineering technical support, and construction guidance. This ensures a seamless procurement experience for customers sourcing Alumina Ceramic Lined Tubes, Ceramic Lined Elbows, and Al₂O₃ Ceramic Wear Pipe.

Powder Conveying Systems

Suitable for highly abrasive conditions in cement plants, quartz sand, bauxite, pulverised coal, etc.

Minerals Slurry Conveyance

Sand pumps, tailings pipelines, environments with large particle impact

Flue Gas Desulphurisation Systems

In corrosive media conditions, enterprises typically select alumina ceramic-lined tubes and alumina ceramic pipes as primary conveyance pipelines.

|

Project |

Ordinary steel pipe |

composite pipe |

Alumina Ceramic Lined Pipe (Qi Shuai) |

|

Abrasion resistance |

★☆☆☆☆ |

★★★☆☆ |

★★★★★ |

|

lifespan |

6–12 months |

1–2 years |

5–10 years or more |

|

Corrosion resistance |

Medium |

Good |

Excellent |

|

Weight |

Heavy |

Medium |

Moderately light |

|

Number of maintenance operations |

frequently |

Occasionally |

Extremely low |

|

Cost-effectiveness |

Low |

Medium |

extremely high |

Exceptionally High Wear Resistance. From raw materials with ≥92%, 95%, or 99% Al₂O₃ sintered at 1700°C. The wear resistance is superior to manganese steel by more than five times. Suitable for operating conditions with high abrasion and high impact.

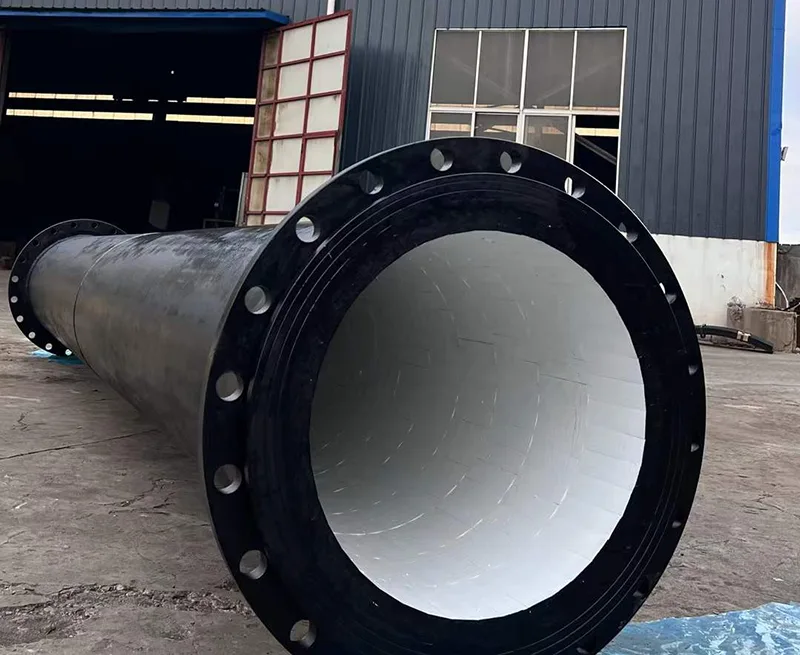

Various Methods for Installation. We provide various interface types such as welded, locking and flanged interfaces so that you can adapt Bushings to various straight pipes, elbows, tees etc. especially suitable for long-term operation in pipeline systems with powders, slurries and mortars, such as Ceramic Lined Elbows.

Excellent Corrosion Resistance and Resistant to High Pressure. Isostatically pressed ceramic wear tubes are denser structures using isostatic pressing technology, which can be applied in highly corrosive and high pressure conveying environment, and life span will be greatly improved compared with conventional lined pipes.

Gutterous Inner Wires, Low Energy Consumption. Surface finishing can be reached at 0.2μm, which can reduce conveying resistance and improve efficiency. Long-term operation can further reduce energy consumption and maintenance costs.