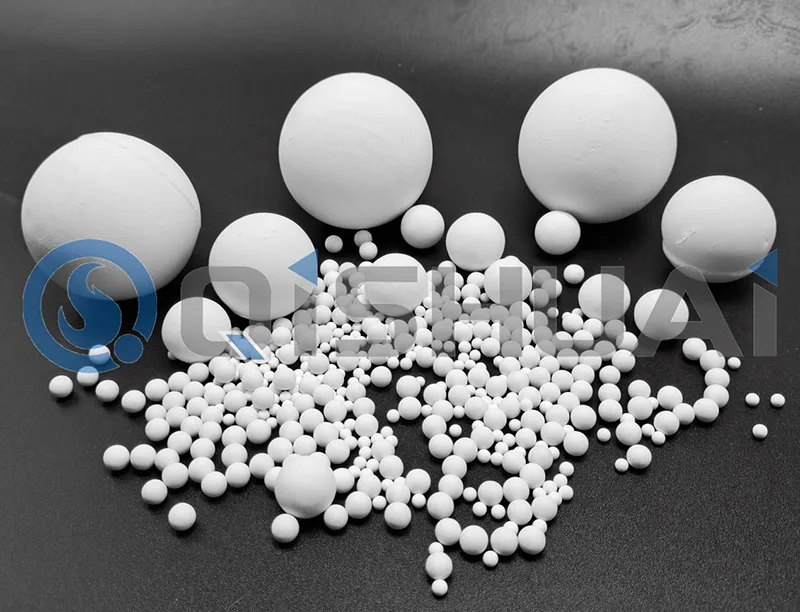

From pulverisation, spray granulation, isostatic pressing, high-temperature tunnel kiln sintering, through ultra precision testing to inspection, sinterising, sorting, screening, blending and final packaging and dispatch, our every batch of alumina ceramic balls are digitalised to international advanced standards for hardness, wear and fracture resistance.

Send Email For Ball Mill Ceramic Liner We have all kinds of ball mill liner to meet your needs,also the following products for your reference.

Send Email For Alumina Balls We have all kinds of high density alumina balls for sale,also the following products for your reference.

Send Email For Alumina Ball We have all kinds of alumina balls for sale,also the following products for your reference.

Send Email For Alumina Grinding Ball We have all kinds of high density alumina balls for sale,also the following products for your reference.

Own manufacturing facilities + ample inventory enable 7–15 day expedited shipping for overseas orders. Supports FOB/CIF trade terms, ideal for long-term bulk procurement.

High Alumina Formula, Ultra High Sintered Density.

Our Alumina Balls / Al₂O₃ Balls use a 92%-95% alumina formula, which greatly reduces the consumption of grinding media.

Extremely low wear rate, applicable for long-term continuous grinding process.

Test data: Alumina Grinding Ball Wear rate ≤0.015%.

Drastically reduce the purchase cost per unit and the frequency of maintenance, improve the ROI of the whole line.

Ultra-hardness (Hardness of Mohs 9) that the ceramic balls will not be crushed by the violent grinding impact and no iron pollution will happen.

Perfectly matched with coatings, electronic ceramics, lithium battery materials and industries.

High mechanical strength, will not be broken and polluted Optimize for ball mill, The mechanical performance of the ball mill is increased by 20%-40% when using with our Ball Mill Ceramic Liners.

|

Items |

Alumina Balls |

Al2O3 Ball |

Alumina Grinding Ball |

|

Al2O3 content |

92–95% |

95% |

92–95% |

|

Bulk density |

1.45–1.55 g/cm³ |

1.55 g/cm³ |

1.48–1.58 g/cm³ |

|

Hardness (Mohs scale) |

≥9 |

≥9 |

≥9 |

|

abrasion |

≤0.015% |

≤0.01% |

≤0.015% |

|

Applicable applications |

Ball milling media |

High-purity grinding |

Long-cycle grinding |