Company Strength: Your Most Trustworthy Wear Protection Partner!

Established in, we have been engaged in the wear-resistant field for many years.Shandong Qishuai Wear Resistant Equipment Co., Ltd.has rich technical strength and strict quality control over the production process.We can guarantee the whole process from raw material to finished product. Our ceramic rubber linings is your most worthy partner in the market, tested by the market, and we also provide you with professional technical support!

In addition to the standard products, we can also provide you with custom design according to the working environment you apply for so that the lining in any part will be used in the best state.

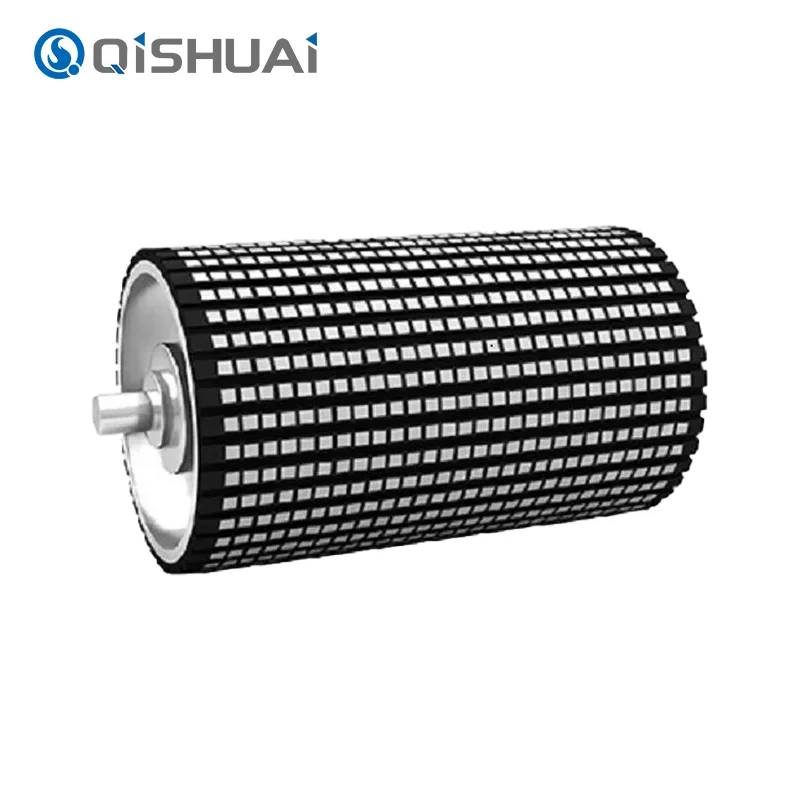

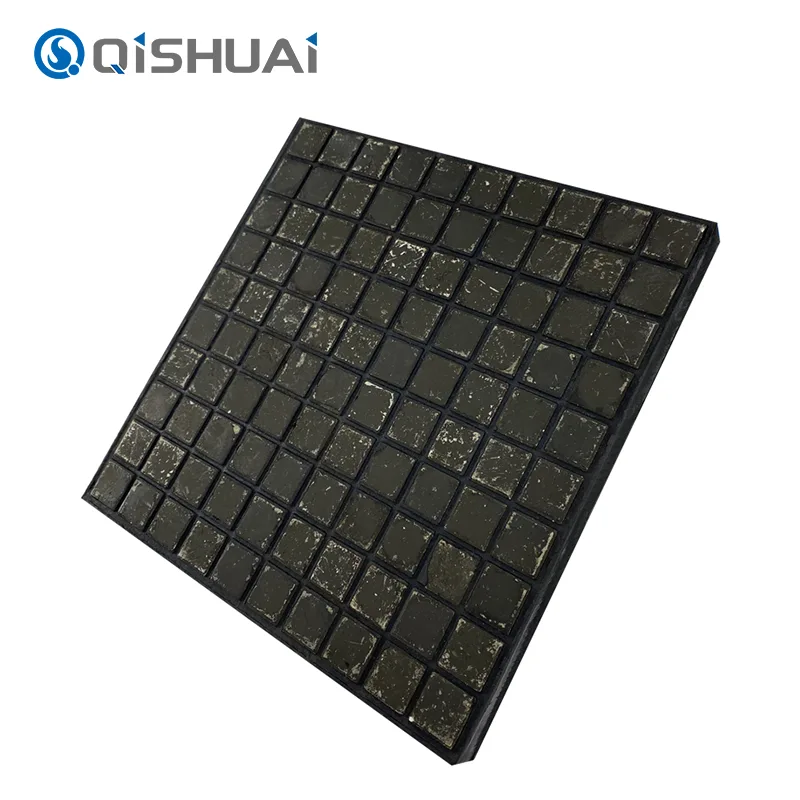

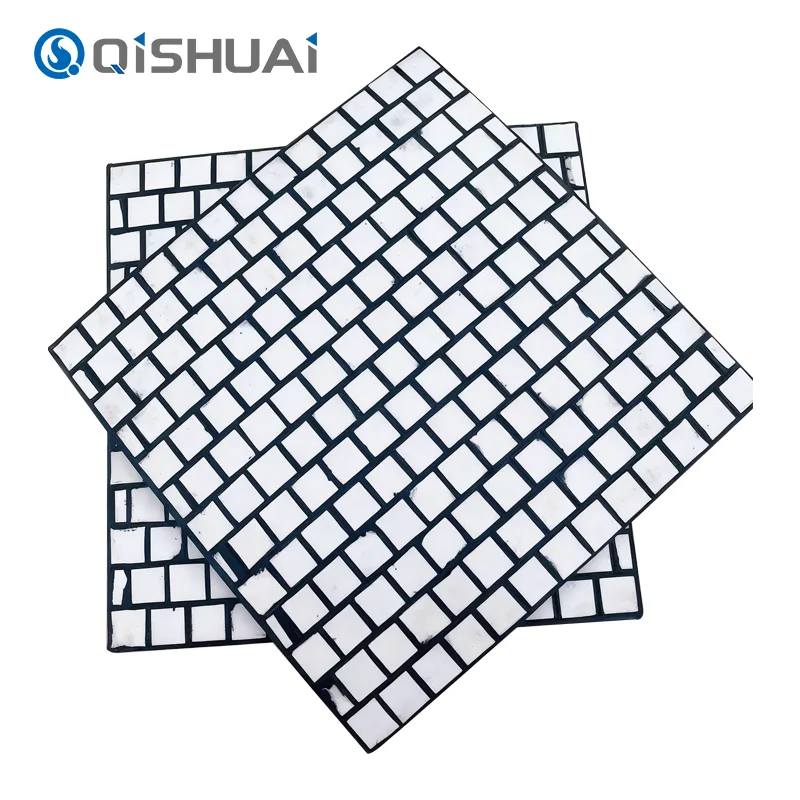

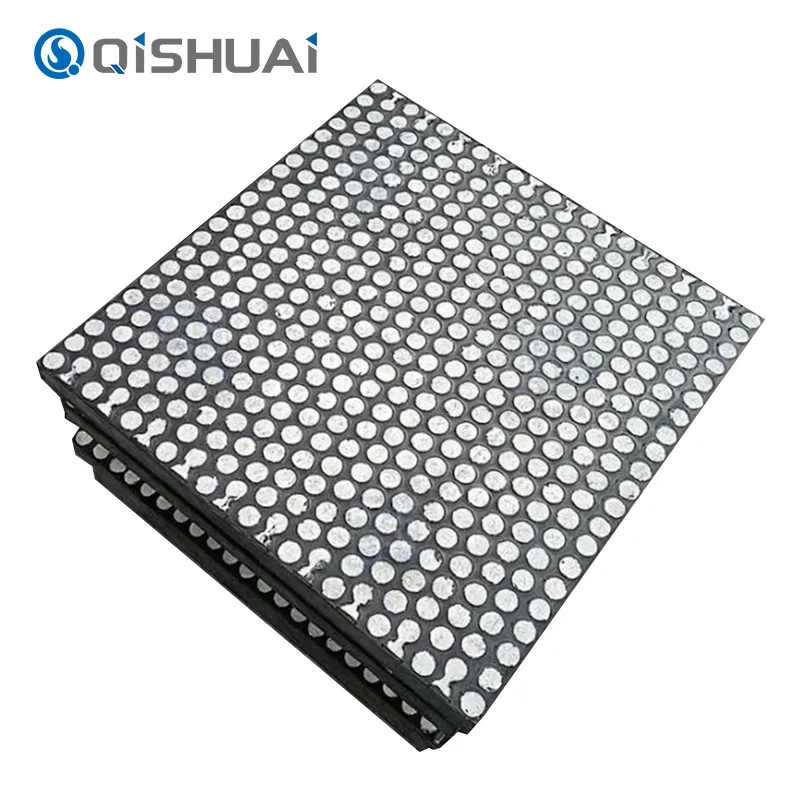

Our company's ceramic rubber linings combine high-hardness, high-wear-resistant alumina ceramics with high-elasticity, high-toughness special rubber, creating a synergistic effect that is greater than the sum of its parts.

Excellent wear and impact resistance: The surface alumina ceramic layer (hardness up to Hv900 or higher) effectively resists abrasive wear from materials, while the underlying rubber absorbs the kinetic energy of material impacts through elastic deformation, greatly reducing the risk of breakage caused by impact. This structure makes it particularly outstanding in complex working conditions involving both high wear and high impact.

Excellent anti-blocking and noise reduction effect: The bottom elasticity of rubber and the smoothness of the ceramic surface can prevent materials from sticking and plugging, solving the blocking problems occurred in the hopper and chute. Meanwhile, the rubber itself also has good sound absorption and vibration absorption performance, reducing the noise during the process of handling materials and creating a good working environment.

Lightweight & Easy Installation: Contrasted with pure steel and solid ceramic lining, ceramic-rubber lining is much lighter, and lower equipment load. Product design is very flexible, it can be bolt fixing, bonding or other ways, simple installation and greatly shortened downtime for maintenance.

Our Ceramic Rubber Liner are widely used in the following areas for wear and corrosion protection:

Thermal Power Generation: Coal powder conveying systems, coal chutes, hoppers, dust removal pipelines.

Iron and Steel Metallurgy: Conveying chutes for ore, sintered ore, and coke; blast furnace pulverized coal injection pipelines.

Coal Mining: Screening equipment liners, coal washing chutes, ore loading bins.

Cement and Building Materials: Chutes and conveying pipelines for raw materials, clinker, and cement.

The table below lists the standard technical parameters of our ceramic-rubber linings. You can refer to and select based on your specific needs:

|

Technical Parameters |

Standard specification range |

Notes and Instructions |

|

Ceramic Specifications |

10x10, 17.5x17.5, 20x20 (mm) etc. |

Can provide customization of various shapes and thicknesses |

|

Ceramic Hardness |

≥ Hv850 |

High-purity alumina ceramics ensure core wear resistance |

|

Rubber Layer Thickness |

5mm - 25mm |

Choose according to impact strength, customizable |

|

Overall Thickness |

15mm - 45mm |

Comprehensively consider wear life and installation space |

|

Bonding Strength |

≥ 8 MPa |

Ceramics and rubber are chemically vulcanized and bonded, never falling off |

|

Main Installation Methods |

Fixed with holed bolts, bonded with high-strength adhesive |

Provide installation guidance and technical support |

In a highly competitive market, Shandong Qishai's ceramic rubber lining stands out, and the secret lies in our meticulous attention to detail. We utilize a unique "high-temperature and high-pressure vulcanization" process, ensuring a strong bond between the ceramic and rubber at the molecular level, completely eliminating detachment during use. Furthermore, our carefully selected rubber formula not only possesses excellent elasticity but also boasts superior corrosion resistance and anti-aging properties, maintaining stable performance even in humid, acidic, and alkaline environments. When considering a complete solution, our composite pipes and alumina ceramic series products serve as perfect complements to pipeline systems and elbow sections, building a comprehensive wear-resistant defense.

Choosing the right wear-resistant lining is a crucial step in optimizing production efficiency and reducing costs. We recommend that you provide us with detailed information about your working conditions before purchasing, including: material type, particle size, drop height, flow rate, and operating temperature. Our technical team will then recommend the most suitable ceramic rubber lining product specifications and installation plan for you.

Act now and provide your equipment with top-tier protection! Feel free to contact us anytime via website inquiry, phone, or email to obtain a customized quote and detailed technical information. Shandong Qishai Wear-Resistant Equipment Co., Ltd. looks forward to becoming your reliable partner, jointly improving your equipment durability and production efficiency!

Should you have any enquiries regarding our products, please do not hesitate to contact us via the following methods:

Telephone:+86-533-7010227

WhatsApp:8615898737636 (Kella)

WhatsApp:8618953367229 (Penny)

WhatsApp:8613869372890 (John)

Email:qishuai@zbqishuai.cn