Shandong Qishuai Wear Resistant Equipment Co., Ltd. is your best factory direct price and wholesale custom manufacturing factory of unique alumina ceramic special components supplier to all global buyers.In the highly competitive industrial wear resistant materials industry, finding a supplier who can provide quality and accurate products and the best price is very important. At Shandong Qishuai, we are not just selling products, we are selling carefully crafted solutions to increase the life time of your equipment.

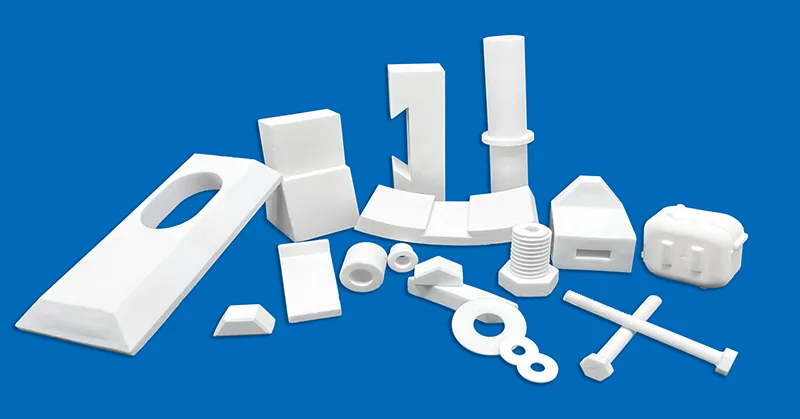

All of our customized alumina ceramic components are produced with isostatic pressing and high-temperature tunnel kiln firing methods. Every of our manufactured and exported products are designed to meet the requirements of mining, cement, thermal power generation and steel industries. Unlike the tiles, the customized components according to your needs are designed for irregular geometries and provide 360 degree protection for your machines.

To meet diverse customer requirements, we have categorised our high-performance ceramics into specific sub-products. Depending on your particular wear scenario, you may browse the following specialised sections:

Complex Machinery Linings:

For equipment featuring curved, conical or irregular surfaces, our bespoke [alumina ceramic custom-shaped components] are the ideal solution. These components are pre-engineered to interlock seamlessly like puzzle pieces, ensuring the lining system presents no weak points.

Pipework and Cyclone Protection:

For internal protection of pipework and cyclones—where uninterrupted flow is paramount—we recommend our high-precision [alumina cylinders]. Featuring smooth internal surfaces, these cylinders minimise friction while delivering maximum wear protection.

To assist engineers and procurement personnel in making informed decisions, the following is our detailed technical specifications table.

|

Property |

Unit |

92% Series |

95% Series |

ZTA Series |

|

Alumina Content (Al2O3) |

% |

≥ 92 |

≥ 95 |

Zirconia Toughened |

|

Density |

g/cm³ |

≥ 3.60 |

≥ 3.65 |

≥ 4.10 |

|

Vickers Hardness (Hv50) |

GPa |

≥ 10.5 |

≥ 11.5 |

≥ 12.5 |

|

Fracture Toughness |

MPa·m1/2 |

3.5 - 4.0 |

4.0 - 4.5 |

≥ 5.5 |

|

Wear Loss |

cm³ |

≤ 0.02 |

≤ 0.01 |

≤ 0.008 |

|

Equivalent Wear Life |

Ratio |

10x vs Steel |

12x vs Steel |

20x vs Steel |

Quality is the lifeline of Shandong Qishuai. Our manufacturing process for specialised alumina ceramic components incorporates stringent quality control measures. Every stage—from the screening of high-purity alumina powder through spray granulation to final sintering—is meticulously monitored.

Our equipment includes:

Automatic presses: Ensuring uniform density in every component.

High-temperature tunnel kilns: Guaranteeing consistent firing results and ceramic structure integrity.

Laser inspection: Validates dimensional accuracy of irregular components, ensuring straightforward on-site installation.

Our Oxide Ceramic Special Shaped part find extensive use across industries where ‘wear’ poses daily challenges.

Mining: Chutes, hoppers, and transfer points where ore impacts walls.

Cement plants: Separator blades, mixer linings, and cyclone feed pipes.

Power Generation: Coal handling systems, pulverised coal pipelines, and ash removal systems.

Lithium Battery Industry: Protecting equipment from metallic contamination (as our ceramics are metal-free).

Q: What is the minimum order quantity (MOQ) for custom parts?

A: We operate as a flexible manufacturer. Whilst we encourage bulk wholesale orders for optimal pricing, trial orders are also accommodated. Please contact us for a quotation.

Q: Can you design shapes if we only provide equipment drawings?

A: Absolutely! Our engineering team can analyse your equipment drawings (CAD/PDF format) and design corresponding alumina ceramic special parts to ensure perfect fitment.

Q: How are these irregular parts packaged?

A: We utilise fumigation-free wooden pallets and boxes with foam cushioning to prevent damage during sea transport.