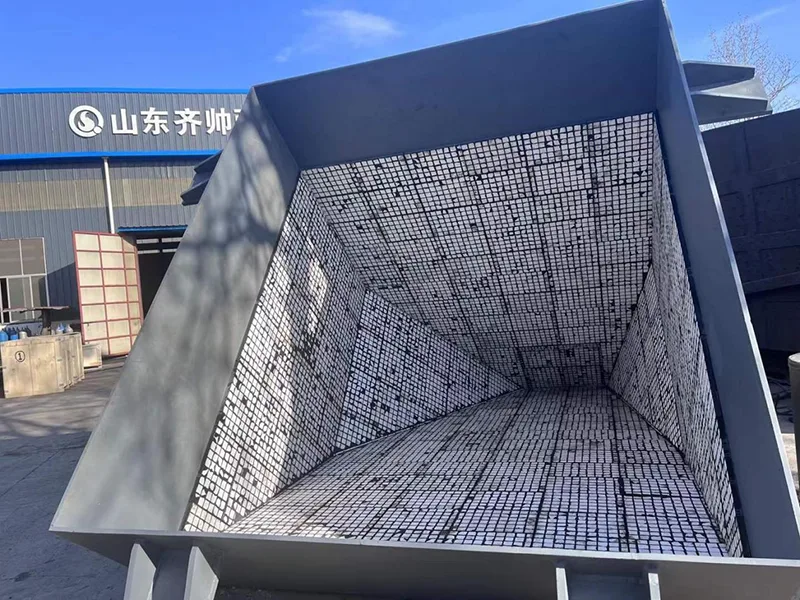

In heavy industries such as thermal power generation, steel smelting, and mining, the core components of material handling systems—such as large storage silos, discharge points tens of meters high, and screening equipment subjected to continuous high-intensity vibration—place extremely demanding requirements on the reliability of protective materials. For a long time, the industry has faced a difficult choice: using high-toughness metal liners, but having to tolerate their drawbacks of easy deformation, high noise, and rapid wear; using extremely wear-resistant pure ceramic liners, but having to contend with their high brittleness, susceptibility to impact, and complex installation process; and relying on elastic rubber linings, which often suffer from insufficient surface wear resistance, leading to premature wear. This material dilemma of "impact resistance without wear resistance, and wear resistance without impact resistance" has become a prominent bottleneck leading to unexpected production interruptions, high maintenance costs, and impaired overall energy efficiency. To fundamentally solve this problem, Shandong Qishuai Wear-Resistant Equipment Co., Ltd. has launched a ceramic rubber embedded steel liner. This product provides an unprecedented integrated solution for extreme working conditions.

Ceramic Rubber Embedded Steel Liner embedded steel liner adopts an original "rigid-flexible-rigid" composite structure, with each layer precisely calculated and engineered to complement the functions of the others:

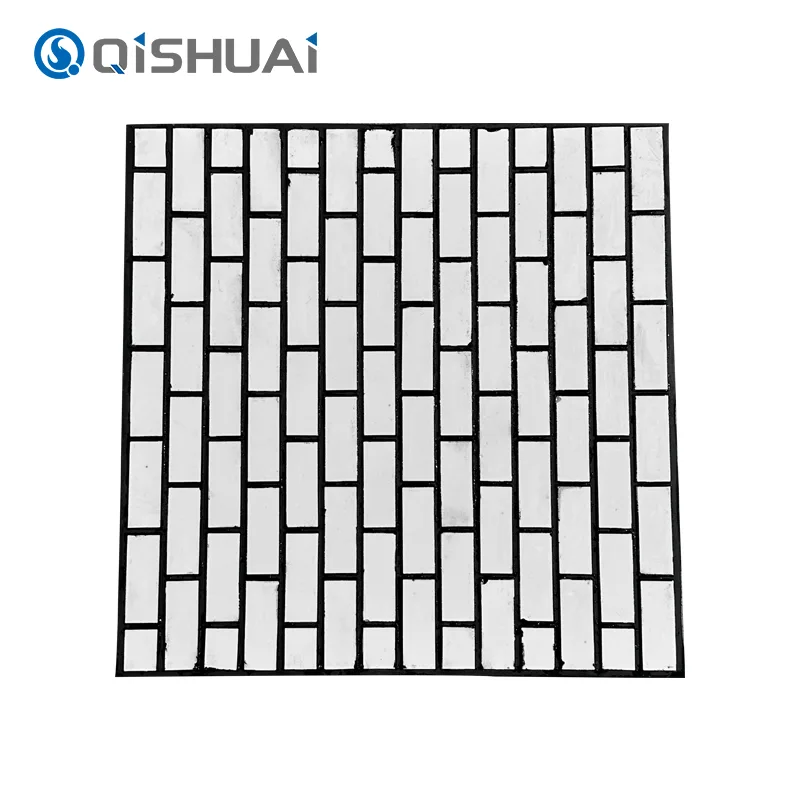

1. Surface Armor: Utilizing high-purity, high-density alumina ceramic blocks, it provides surface hardness (Hv≥850) several times greater than steel, directly resisting cutting and abrasive wear from materials.

2. Intermediate Flexible Core: A special synthetic rubber layer acts as the core energy absorption zone. Through its excellent elastic deformation, it effectively cushions the impact kinetic energy of materials up to several joules, eliminating stress concentration and protecting the ceramic from shattering and the steel base from deformation.

3. Bottom Steel Frame: A high-strength steel plate serves as the skeleton of the overall structure. The ceramic blocks are embedded in the vulcanized rubber layer using precision molds, forming an inseparable integrated module. This steel plate is directly welded to the equipment body, providing unparalleled connection strength and completely eliminating the risk of detachment.

Choosing Shandong Qishuai's ceramic-rubber embedded steel lining means you are choosing the following values for your equipment:

Exceptional ability to withstand extreme impacts: Its unique "embedded" structure evenly disperses the impact force from the ceramic surface through the rubber layer to the entire steel base plate, improving impact resistance by more than 300% compared to adhesive linings, making it particularly suitable for environments with continuous impact from large, sharp materials.

Ultimate Convenience in Installation: As a prefabricated module with a steel backing plate, on-site installation only requires lifting, positioning, and welding. Construction efficiency is several times higher than traditional small-piece bonding or bolt fixing methods, significantly shortening downtime on the critical path.

Optimal life-cycle cost: Although the initial investment may be slightly higher, its exceptionally long service life (typically 5-8 times that of manganese steel plates), zero maintenance costs, and production assurance by avoiding unplanned downtime result in significant overall economic benefits. For higher temperature or highly corrosive environments, it can be combined with our Ceramic Rubber Embedded Steel Liner series for customized designs. For higher temperature or highly corrosive environments, it can be combined with our silicon carbide ceramic series products for a combined design.

|

Item |

Technical Parameters/Description |

Design Basis and Advantages |

|

Composite Unit Structure |

Ceramic/Rubber/Steel Plate Integrated Vulcanized Module |

Fundamentally solve the falling-off problem and bear core patents |

|

Ceramic tile specifications |

Custom square/hexagon, thickness 15-30mm |

Optimize the arrangement to reduce seams and enhance integrity |

|

Thickness of steel substrate |

6-20mm (Q235B/wear-resistant steel) |

Ensure the overall rigidity based on the calculation of impact load |

|

Shore hardness of the rubber layer |

60°A ±5 |

Balance buffering and support to avoid ceramic vibration caused by excessive softness. |

|

Installation method |

Continuous welding of the steel base plate and the equipment shell |

Highest connection strength, good sealing performance, no circulation gaps |

|

Applicable temperature range |

-30°C ~ +100°C(short-term120°C) |

Stable over a wide temperature range, with customizable special rubber formulations |

|

Relative wear resistance |

8-10 times that of 16Mn steel |

Tested in accordance with GB/T3960-2016 standard |

Shandong Qishai Wear-Resistant Equipment Co., Ltd. provides not only individual products but also systematic solutions. The ceramic rubber embedded steel lining, acting as a "heavy-duty armor" against the strongest impact and abrasion, seamlessly integrates with the company's other flagship products:

For pipe bends where material changes direction, composite pipes are the ideal choice due to their excellent resistance to centrifugal wear.

For straight pipe sections with moderate impact and primarily sliding wear, the Ceramic Rubber Embedded Steel Liner provides cost-effective protection.

For localized or irregularly shaped parts requiring on-site welding repair, the chromium carbide hardfacing series provides a rapid response.

If your equipment is suffering from frequent impact and abrasion damage, please contact us following these steps to obtain a customized ceramic-rubber embedded steel lining solution:

1. Provide operating condition information: Please prepare equipment drawings, material characteristics (particle size, specific gravity, humidity), drop height, temperature, and current maintenance cycle data.

2. Technical solution consultation: Our engineers will analyze the data, perform impact energy calculations, and provide you with the optimal structural design and module division plan.

3. Samples and trial installation: We can provide small samples or trial installation modules for on-site verification.

4. Mass production and delivery: After the solution is confirmed, the manufacturing line will be activated to ensure high-quality delivery.

Welcome to click "Contact Us" to submit your operating condition information and obtain a preliminary design plan. Shandong Qishai, with structural innovative technology, protects the long-term stable operation of your heavy equipment.

Should you have any enquiries regarding our products, please do not hesitate to contact us via the following methods:

Telephone:+86-533-7010227

WhatsApp:8615898737636 (Kella)

WhatsApp:8618953367229 (Penny)

WhatsApp:8613869372890 (John)

Email:qishuai@zbqishuai.cn