Shandong Qishuai Wear-Resistant Equipment Co., Ltd. has specialised in the ceramic industry for over a decade, establishing itself as a key wear-resistant materials manufacturing base in Northern China.

Industrial-grade R&D System: Equipped with a specialised bonding laboratory, ensuring consistent and superior performance metrics for our product, including curing speed, shear strength, and temperature resistance.

International Export Certification: Products are exported to over 40 countries, meeting quality standards for markets including Europe, America, Southeast Asia, and the Middle East.

Extensive Engineering Implementation Experience: Completed over 2,000 wear-resistant lining plate bonding projects across mining, cement, power generation, and steel sectors.

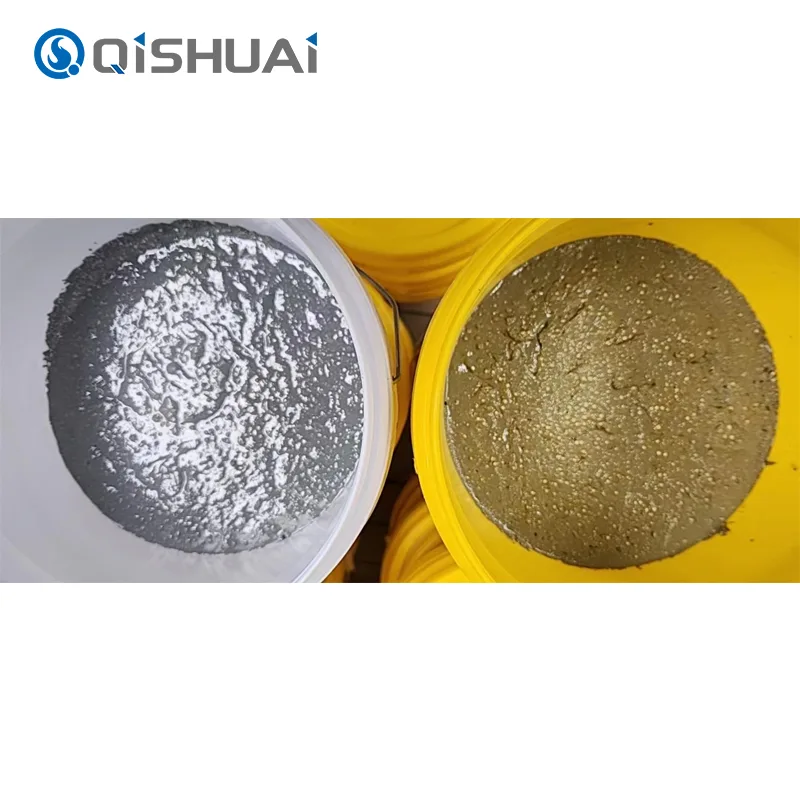

To meet the requirements of various operation conditions, our product uses epoxy resin modified with nano-particle toughening agents, which can apply in extreme conditions.

High Bond Strength(≥25MPa)Applicable for aluminium oxide ceramic tile, ceramic tube, metal and rubber.

High Temperature and Wear Resistant The cured resin layer can maintain over 150℃ for a long time.

Demonstrates outstanding resistance to acids, alkalis, and solvents, eliminating concerns over delamination or chalking.

Broad compatibility (universal across multiple industries)

Widely procured by mining, port, steel, chemical, metallurgical, cement and other sectors.

Simple application, rapid curing

Can be applied directly on-site without high-temperature conditions, reducing maintenance costs.

Used for bonding ceramic liners to metal surfaces, this is the most widely applied grade among high-strength industrial adhesives. Its characteristics include exceptional shear strength, outstanding wear resistance, and excellent toughness after curing.

Suitable for repairing equipment cracks and reconstructing worn surfaces, commonly used for repairing hoppers, pump casings, ductwork and damaged liners. A staple procurement item for maintenance departments.

|

Parameters |

Numerical range |

Note |

|

viscosity |

25,000–60,000 cps |

Suitable for scraping and dotting |

|

Shear strength |

≥25 MPa |

Above the industry average |

|

Curing time |

Initial setting: 3–4 hours / Full setting: 24 hours |

The higher the temperature, the faster the process. |

|

Temperature range |

-40℃ ~ 150℃ |

Short-term temperatures may reach 180°C |

|

Chemical resistance |

Acid/alkali/salt spray/solvent |

Long-term corrosion resistance |

|

Shelf life |

12 months |

Store in a cool, dry place. |

Exceptional durability and stable wear resistance

Optimised for ceramic substrates to enhance bonding strength

Versatile application across environments without requiring high-temperature equipment

Ideal for bulk project procurement with robust supply capacity

Consistently favoured by multiple cement manufacturers and mining groups

Supports rapid dispatch with export packaging and multilingual documentation