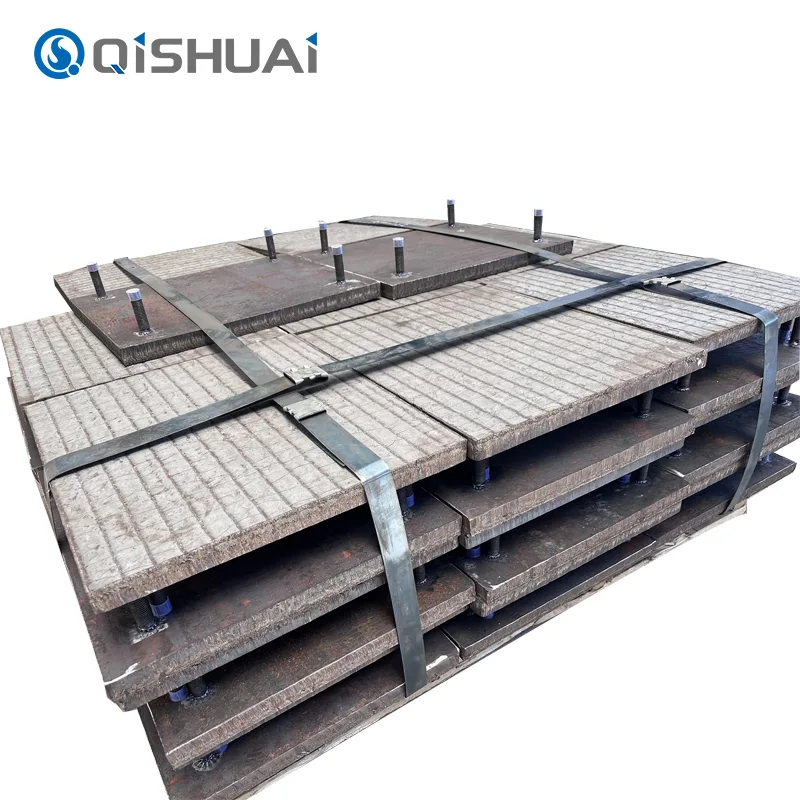

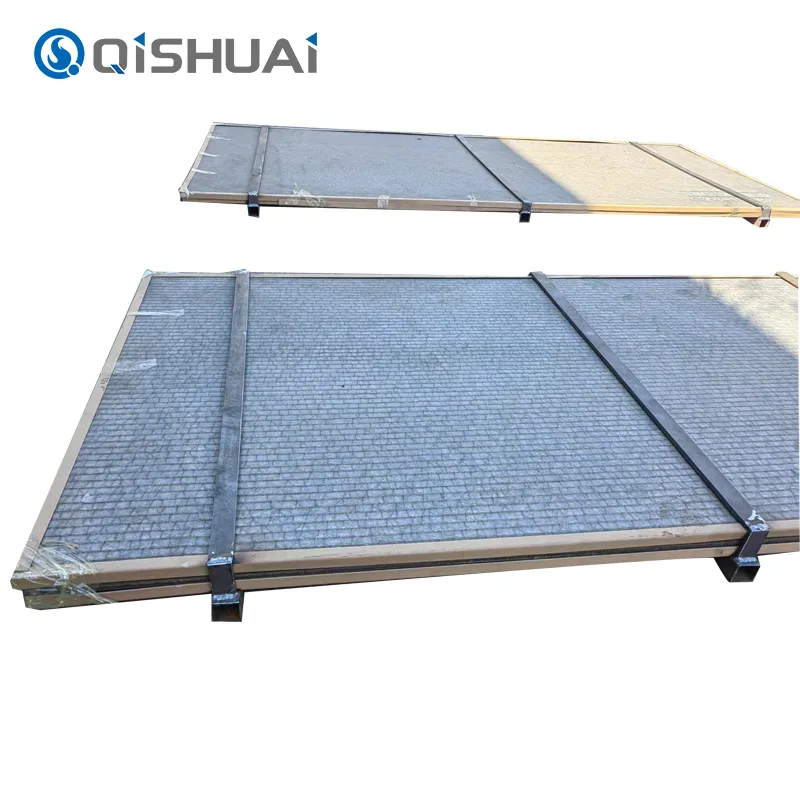

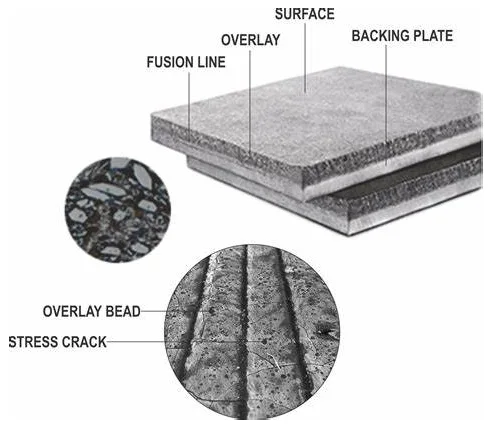

Chromium Carbide Overlay Plate is the core product with highest performance as wear-resistance company– Shandong Qishuai Wear-Resistant Equipment Co., Ltd. It is integrated by low carbon steel substrate and chromium carbide wear-resistance coating on its surface, which is coated by advanced overlay welding technology. The product combines the toughness and structure protection of substrate and the extremely wear-resistance of chromium carbide coating.

1. Scientifically proportioned substrate and wear-resistant layer

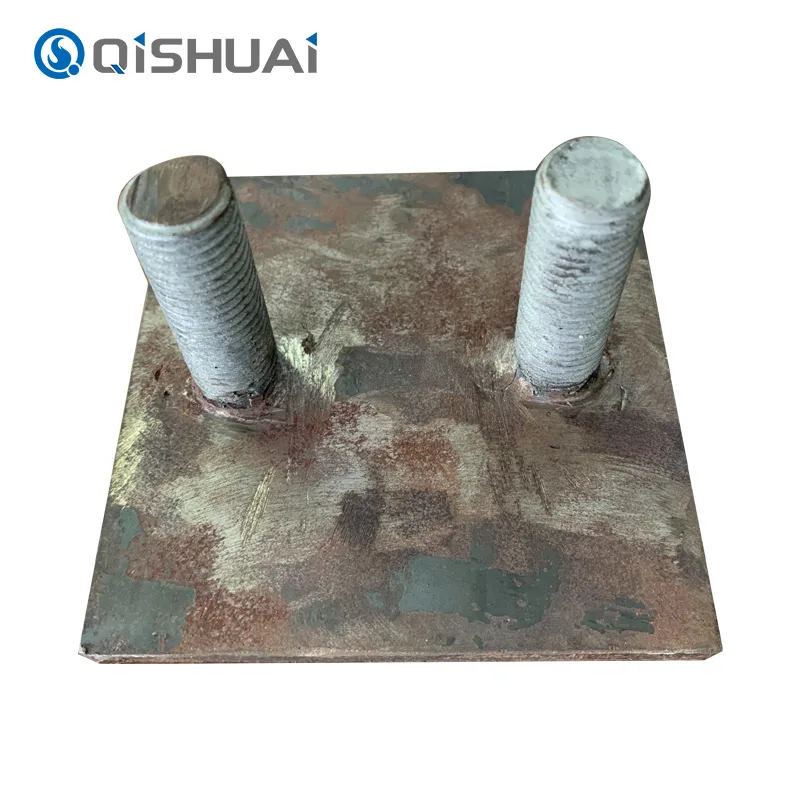

Base plate material: Primarily utilises low-carbon steels such as Q235 and Q345 to ensure overall structural strength and machinability.

Wear-resistant layer composition: Chromium carbide (Cr₃C₂) serves as the core hard phase, achieving a hardness of HRC 60-68 to form a dense protective layer.

2. Process Advantages

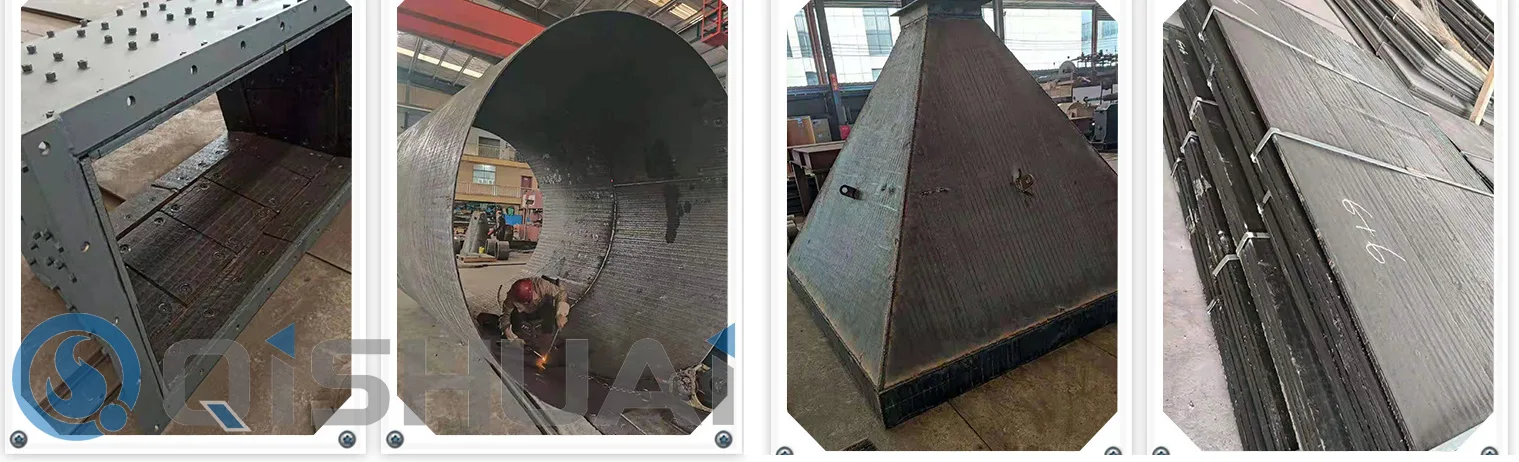

Because Shandong Qishuai uses automatic open-arc welding or submerged arc welding, chromium carbide particles are evenly dispersed and metallurgically bonded to the base material. There is no danger of delamination.

3. Performance Characteristics

Impact Resistance: Because the substrate absorbs impact and the wearing layer resists wear, this substrate is suitable for relative impact situations.

Corrosion Resistance: Chromium resists oxidation and corrosion from weak acids and alkalis.

Flexibility: According to the size and shape of the equipment, there is no limit to the installation requirements.

1. Technical Assurance

With 15 years of R&D experience in wear-resistant products, we conduct full inspections on every plate for hardness, bond strength, and dimensional tolerances.

2. Comprehensive Cost Advantage

Though the initial purchase cost is slightly higher, our plates last 5-8 times longer than standard steel plates, significantly reducing replacement frequency and downtime losses.

3. Service Support

We provide operational condition assessments and selection recommendations to match the optimal solution.

4. Ecological Synergy

Our products integrate seamlessly with our alumina ceramic series and composite pipes. For instance, rubber-ceramic composite plates can be installed in impact zones while chromium carbide clad plates cover wear areas, enabling comprehensive scientific protection for entire equipment lines.

Cement Industry: Chromium carbide cladding plates for cement industry grinding roller of vertical mill, service life is 18 months.

Coal Mining Industry: Chromium carbide cladding plates for conveyor chute wear-resisting, the mining company reduce the annual wear rate of 70%.

Power Generation Industry: High temperature cladding plates for wear-resisting in coal mill inlet cone.

Chrome Carbide Overlay Plates introduces wear-resistant equipment to all our customers in an efficient way and long wearing life time!Call me immediately if you need any help about the specification of chromium carbide overlay plates or need to apply for sample!

Shandong Qishuai Wear Resistant Equipment Co., Ltd.also can supply you with a whole set solution with alumina ceramic series and rubber ceramic composite plates!