Shandong Qishuai Wear-Resistant Equipment Co., Ltd. supplies high-performance composite wear pipes, delivering conveying solutions with extended service life, reduced maintenance costs, and enhanced impact resistance for clients across mining, steelworks, cement, port, and power industries. Whether you require a reliable global supplier, bulk procurement, or bespoke wear-resistant piping systems, Qishuai delivers truly high-standard industrial products through its rigorous manufacturing systems and international service capabilities.

Corporate Strength – A Globally Recognised Industrial-Grade Supplier

Shandong Qishuai Wear-Resistant Equipment Co., Ltd. has specialised in wear-resistant products for over a decade. We export to more than 30 countries, providing long-term supply solutions for international mining engineering companies, equipment manufacturers, and EPC contractors.

Our product is one of our core products, featuring stable delivery cycles to meet the procurement demands of large-scale projects.

Core Product Benefits – Tri-functional Assembly of Wear Resistance, Impact Resistance and Corrosion Resistance.

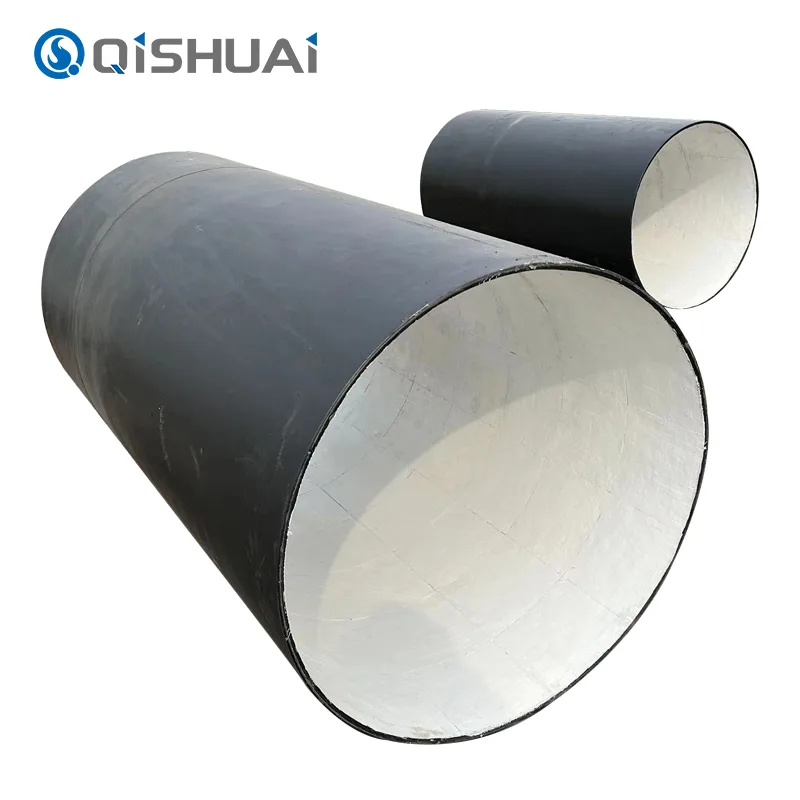

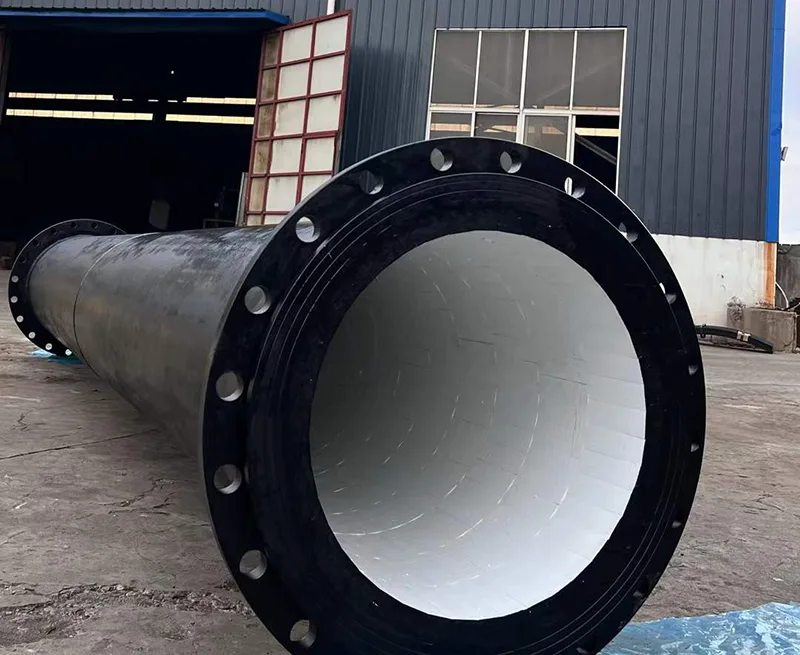

Compared with normal steel pipes, Shandong Qishuai Wear-Resistant Equipment Co., Ltd. Composite Wear Pipe has the following characteristics formed from assembly of high-alumina ceramic, silicon carbide and steel pipe produced by sintering process combined with high strength bonding/welding process.

• Wear life is improved 8–12 times.

• Smooth inner ceramic layer improves conveying efficiency.

• Resists over high impact force without delamination.

• Can be used for -50°C to +1000°C environment for long time.

• Coal dust, mineral powder, slurry, mortar, ash residue, granular material.

In the routine project procurement, the following pipes are usually chosen by clients.

Isostatic Pressed Alumina Ceramic Lined Pipe (High Wear Resistance Type).

Alumina Ceramic Mosaic Lined Pipe (High Cost Effectiveness Type).

Silicon Carbide Lined Wear Pipe (High Temperature, Strongly Corrosive Environment Type).

|

Product Type |

Lining material |

Abrasion resistance grade |

Temperature range |

Service life |

Recommended Industries |

|

Alumina Ceramic Lined Pipe |

92%–95% Al₂O₃ |

★★★★★ |

≤800°C |

is 8–12 times that of steel pipes |

Mining/Power Plant |

|

Alumina Mosaic Lined Pipe |

Alumina ceramic mosaic tiles |

★★★★ |

≤700°C |

is 5–8 times that of steel pipe. |

Cement/Dock |

|

Silicon Carbide Lined Wear Pipe |

SiC ceramics |

★★★★★+ |

≤1200°C |

is 10 -15 times that of steel pipes |

Metallurgy/Chemical Engineering |

Each of the above products can be selected via the respective links to view detailed specifications:

➡ View details of isostatic pressure ceramic-lined pipes

➡ View details of mosaic ceramic-lined pipes

➡ View details of silicon carbide-lined pipes

Our Composite Wear Pipe finds extensive application in:

Ore conveyance pipelines

Pulverised coal transport systems

Mining plant slurry pipelines

High-temperature ash discharge

Port unloading systems

Chemical corrosion medium conveyance

Qishuai offers purchasers:

Customised wear-resistant solutions tailored to operational conditions

Overseas warehousing and expedited logistics (select countries)

Preferential pricing for bulk procurement