Seeking durable our plates? Shandong Qishuai Wear-Resistant Co., Ltd. stands as your trusted manufacturer and supplier, offering global wholesale solutions.

Longer equipment life isn’t just an objective, it’s a requirement in heavy industry. Down time costs you money. Shandong Qishuai Wear Resistant Equipment Co., Ltd. recognize this, and that’s why when it comes to wear resistant technology, you’re buying protection from us, when you buy the plates from us.

When you decide to buy the plates from us, you’re not just buying from a company, you’re buying from a company that has years of experience solving wear problems in mining, cement, power generation, and steel, and we aren’t a trading company, we have our own factory, our plates will definitely reach the quality assurance of ISO.

Factory-direct pricing: Eliminate middlemen to secure the most competitive wholesale rates.

Customisation services: We tailor dimensions, shapes and thicknesses to your specific equipment requirements (e.g., chutes, hoppers, cyclone separators).

Quality assurance: High-purity alumina (92%–95%) guarantees exceptional hardness and impact resistance.

Global export expertise: Professional packaging and logistics support for international buyers.

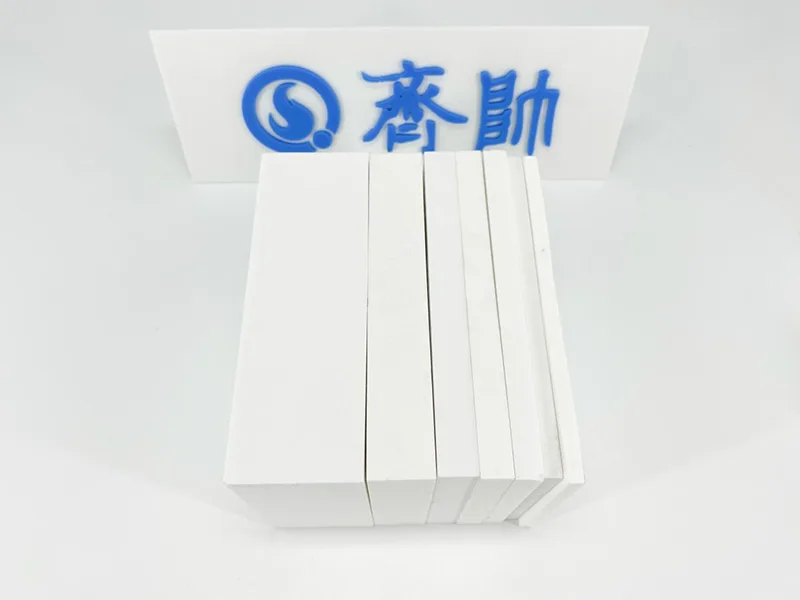

Product Highlights: High-performance alumina ceramic plates

Stock Shandong Qishuai's plates operate in the harshest conditions. Our ceramic materials are sintered above 1500°C and are diamond-like hardness, which is greatly beyond the ordinary steel liners.

Whether you are looking for fixed tiles, weldable tiles, mosaic pads or other, our stocked the plates are wear-resistance, corrosion-resistance and impact-resistance.

Fixed tiles: Alumina Ceramic Wear Plate; Al₂O₃ Ceramic Plate; Alumina Ceramic Wear Liner; Al₂O₃ Ceramic Wear Liner; Alumina Ceramic Abrasion Resistant Liner; Alumina Ceramic Wear Resistant Liner Plate; High Alumina Wear Plate Sheet; Wear Resistant Alumina Ceramic Liner.

Exceptional Hardness: Mohs hardness of 9, second only to diamond.

Lightweight: Its density (3.6–3.7 g/cm³) is half that of steel, reducing equipment load.

Corrosion Resistance: Chemically stable, withstanding acid and alkali corrosion.

Simple Installation: Available in welded, adhesive-bonded, or interlocking configurations.

To assist in making an informed selection and ordering the appropriate specifications, please consult the technical parameters below.

|

Type |

Unit |

92% Series |

95% Series |

|

Al2O3Al2O3

|

% |

≥ 92 |

≥ 95 |

|

density |

g/cm3g/cm3 |

≥ 3.60 |

≥ 3.65 |

|

Vickers hardness(Hv50) |

GPa |

≥ 10.5 |

≥ 11.5 |

|

Fracture toughness |

Mpa⋅m1/2 |

3.5 - 4.0 |

4.0 - 4.5 |

|

Water absorption rate |

% |

≤ 0.01 |

≤ 0.01 |

|

wear |

cm3cm3 |

≤ 0.03 |

≤ 0.02 |

|

Colour |

- |

White |

White |

Our alumina ceramic plates are extensively employed in applications subject to severe abrasion. Should your facility process coal, iron ore, cement clinker or grain, our solutions are precisely what you require.

Mining Industry: Conveyor chutes, vibrating screens and magnetic separators.

Cement Industry: Raw mill pipelines, cyclone separators and limestone hoppers.

Power stations: Coal handling systems, pulverised coal pipelines, and ash removal systems.

Steelworks: Blast furnace hoppers and coke weighing hoppers.

We understand that overseas procurement requires complete confidence in the logistics process. Shandong Qishuai ensures every alumina ceramic plate is securely packaged to prevent damage during transit.

Standard Packaging: Cartons placed on fumigation-free wooden pallets.

Protective Measures: Moisture-proofing with foam layers and plastic film.

Shipping: We support FOB and CIF terms for delivery to major global ports.