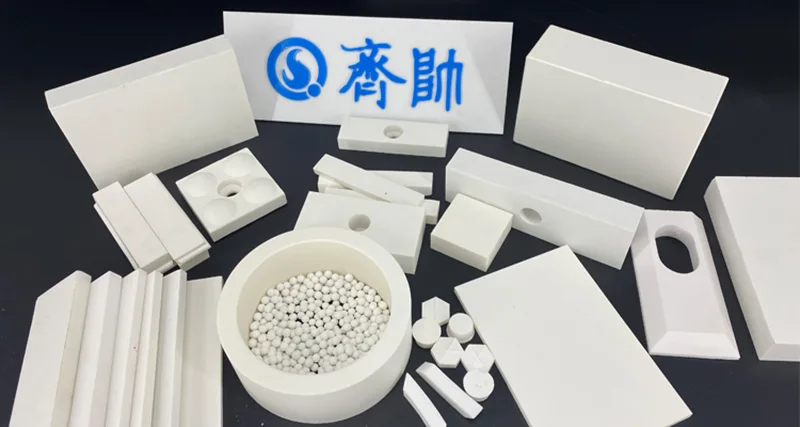

Shandong Qishuai Wear-Resistant Equipment Co., Ltd. specialises in supplying high-quality our product, encompassing six core categories including the Plates, the Lining Bricks, and the Mosaics. We support bulk and customised procurement, delivering wear-resistant protection solutions for global industrial sectors. As a trusted alumina ceramic procurement partner, we provide reliable solutions for diverse applications.

1. Industry Benchmark Capabilities: Leveraging specialised R&D and manufacturing expertise, Shandong Qishuai efficiently fulfils large-scale procurement requirements for its comprehensive product range, including Alumina Ceramic Plates and Ceramic Adhesives. The company holds triple certifications: ISO9001, CE, and SGS. Products are exported to over 30 countries worldwide, serving more than 2,000 industrial enterprises. It has built a strong reputation in mining, metallurgy, chemical, and other sectors.

2. Outstanding Customisation Ability Our team of full-time R&D specialists continually refine alumina ceramic compositions and develop new forming methods. They have mastered isostatic pressing and high-temperature sintering technologies to produce special-shaped oxide ceramic components based on customers’ drawings and working experience. We provide custom solutions from raw material blending to finished products, and our technical service response is among the industry’s best.

3. Quality Control at Every Level, Absolute Assurance in Quality Establish a three-level quality control system of ‘raw materials – production – finished products’. The raw materials use high-purity alumina powder (>99.5%). Production process is monitored by online systems for 24 hours. Finished products are tested with 12 routines, including hardness, wear resistance and temperature endurance. Our entire product range from Alumina Ceramic Balls to customised parts meet the requirement of hardness ≥ HRA90, wear resistance exceeds 30 times that of general steel products, and service life exceeds the industry average by 50%.

|

Product Name |

Core Specifications |

Core performance |

Typical application scenarios |

Procurement Hotspots |

|

Alumina Ceramic Plate |

Thickness: 3–80 mm Dimensions:≤1200×1200 mm (customisable) |

Hardness HRA 88–92, compressive strength≥2000 MPa, temperature resistance 1700°C |

Crusher liner plates, chute base plates, equipment platforms |

Customized alumina ceramic plates, bulk purchase of ceramic plates |

|

Alumina Ceramic Lining Brick |

Standard dimensions: 230×114×65 mm. Custom shapes available upon request. |

Highly wear-resistant, impact-resistant, and easy to lay |

Mill linings, silo linings, flue linings |

Procurement of wear-resistant ceramic lining tiles, industrial ceramic lining tiles |

|

Alumina Ceramic Mosaic |

Particle size: 10×10mm, 15×15mm, etc., can be assembled |

Highly flexible, strong adhesion, flexible application |

Lining for complex curved surfaces and protection for pipe elbows |

Customized ceramic mosaics, purchase of wear-resistant mosaics |

|

Oxide Ceramic Special Shaped part |

Customised to client specifications (tolerance≤ ±0.03mm) |

Performance tailored to requirements, adapted for specific operating conditions |

Precision mechanical components, electronic equipment assemblies, specialised equipment linings |

Customized irregular-shaped ceramic parts and procurement of oxide ceramics |

|

Alumina Ceramic Ball |

Diameter 1–100 mm |

Density: 3.9 g/cm³, Abrasion rate≤0.05% |

Ball mill grinding media, catalyst carriers, bearing balls |

Procurement of high alumina ceramic balls, customization of grinding ceramic balls |

|

Ceramic Adhesive |

Viscosity: 5000–15000 mPa·s Temperature resistance: -40–1200°C |

Bond strength≥3.5 MPa, resistant to acid and alkali corrosion |

Installation and fixing of ceramic products; Repair of equipment wear-resistant layers |

Procurement of high-temperature ceramic adhesives and supply of industrial ceramic adhesives |

1.Shandong Qishuai Wear-Resistant Equipment Co., Ltd.'s alumina ceramic series products stand out in the industrial wear-resistant field due to their superior performance, becoming the preferred choice for many enterprises.

2.Extremely Wear Resistant. The alumina raw material used for the product is of high purity, and the sintering technology is advanced. The wear resistance of the product is much higher than that of conventional metals. For example, the service life of the mill lining using Alumina Ceramic Lining Brick in mining mills is extended from 3 months to 3 years, and the annual maintenance cost is reduced by 80%; The Alumina Ceramic Ball used as the grinding medium increases the grinding efficiency by 40%, and the wear rate is only 1/50 of the steel balls, which greatly reduces the production cost.

3. Corrosion and Temperature Resistance: Alumina ceramics have extremely strong chemical stability and can withstand the erosion of various corrosive media such as strong acids, strong alkalis, and salt solutions. They also maintain stable performance in extreme temperature environments from -50℃ to 1700℃. Whether in the corrosive environment of the chemical industry or the high-temperature working conditions of the metallurgical industry, products such as Alumina Ceramic Plate and Oxide Ceramic Special Shaped parts can operate stably, solving the pain points of traditional materials that are prone to corrosion and aging.

4.Strong Adaptability: Relying on advanced mold manufacturing technology and molding processes, the products have high dimensional accuracy and good surface finish. Alumina Ceramic Mosaic can be flexibly spliced to adapt to various complex curved surface equipment; Oxide Ceramic Special Shaped parts can accurately match customer's special equipment needs, with tolerance control within ±0.03mm, ensuring convenient installation and high fit, without the need for additional processing or adjustment.

5.Environmentally Friendly and Energy Saving: The whole process of manufacturing the product does not pollute the environment and does not emit any pollutants, and the product itself is recyclable and environmentally friendly and conform to the environmental protection system of all kinds of countries. Ceramic Adhesive, the formula contains no solvent, non-toxic and odor-free, no harmful substances are released after bonding; all kinds of alumina ceramic products passed RoHS and REACH, can be used in the food, medicine, electronics and other industries with environmental requirements.

6.Efficient Procurement: We not only provide core products such as Alumina Ceramic Ball and Ceramic Adhesive, but also provide a complete set of wear-resistant protection solutions according to customer needs, including product selection, on-site measurement, installation guidance, and after-sales maintenance services. Eliminate the need to deal with multiple suppliers; a one-stop solution meets all your industrial wear protection procurement needs, significantly improving procurement efficiency.

Alumina ceramic series products, thanks to their excellent performance, are widely used in multiple industrial fields, becoming a core component for wear protection in critical equipment.

Mining Industry: Alumina Ceramic Lining Bricks and Alumina Ceramic Plates are used as linings in equipment such as crushers, ball mills, and vibrating screens to resist ore impact and wear, extending equipment lifespan; Alumina Ceramic Balls are used as grinding media to improve the efficiency and precision of ore grinding.

Metallurgy Industry: Oxide Ceramic Special Shaped parts,the Plate are widely used in steelmaking furnaces, continuous casting machines and conveying pipelines for resisting high temperature, molten steel erosion and material wear, guaranteeing the continuous and stable production.

Chemical Industry: the Mosaic, Ceramic Adhesive can be used as reactor lining, storage tank lining and pipeline anti-wear lining to resist acid and alkali corrosion and material erosion, avoid equipment leakage and guarantee production safety.

Power Industry: Alumina Ceramic Lining Bricks,Alumina Ceramic Plate can be used in boiler flue, pulverized coal conveying pipeline for resisting pulverized coal wear and high temperature corrosion, reduce equipment maintenance cost.

Electronics Industry: Oxide Ceramic Special Shaped parts can be used in electronic component base, insulation bracket for oxide ceramic special shaped parts because it has good insulation performance and high mechanical performance, use it to guarantee the stable operation of electronic equipment.